You may not realize it, but the use of mechanical lubricants has shaped our society from ancient times to the modern day.

But what makes these types of lubricants so important?

Lubricants do much more than just make things slippery.

A lubricant is a substance applied between two surfaces in motion to reduce friction and wear over time. Without these substances at our disposal, modern machinery would break down because of this friction and wear and tear.

There are three basic varieties of lubrication:

- Fluid film – Inserting a fluid film that separates sliding surfaces results in this type of lubrication. They can be introduced intentionally or organically.

- Boundary – With this type, surface friction is based on surface and lubricant properties other than viscosity. They are placed between a fluid film and one non-lubricated surface and are common during the starting and stopping of machines.

- Solid – When normal lubricants do not have enough resistance to high loads or temperatures, solid lubricants can be used. Sometimes metals may even be used as lubricants.

Before we dive deeper into the history of machine lubrication, let’s consider a quick real-world example. Imagine if we didn’t lubricate train wheels and the other mechanical moving components of a train.

The wheels would get rusted and worn, and would not run smoothly across the train tracks. Our train systems would function at a fraction of their maximum capabilities, and sooner or later, they’d break down.

Can you imagine how costly it would be if trains broke down and had to be replaced every few months? And it’s not just for the government and rail companies. It’s for everyday people who rely on trains for transport to and from work.

It’s important to note that when applying a lubricant to a train, it doesn’t get applied to the tracks, but to the wheels, bearings, engines and other moving components. This would result in the train being unable to move because there would be no friction between the tracks and rails. This same concept can be applied to lubricated components across all industries and sectors.

Proper lubrication helps to extend life, improve operational efficiency, and increase safety for trains and their tracks, along with other environmental benefits. And there are countless other examples throughout history too.

Before the Common Era, animal fats and naturally occurring elements were used for lubrication for chariots and in transporting construction materials. Until about the 18th century, these natural methods were still being used, but oil was then designed and developed for specific purposes.

Today, there is much more research and testing, and different materials are being incorporated, such as grease and other synthetic materials. These materials are now thinner than ever and can be applied to tighter spaces, which is important for modern firearms and defense products.

There are specific oils constructed for even more specific purposes, and our machines—from shipping, to transportation, to industrial factories—work faster and more efficiently than ever. Our world could not function as it does today without modern lubrication advancements.

- But how did we get here?

- Who first decided that mechanical lubrication was a good idea?

- And who helped develop these processes over thousands of years to get us to where we are today?

In this article, we will do our best to break these questions down for you by providing the most all-encompassing timeline describing the history of mechanical lubrication on the internet.

Enjoy.

Our Humble Beginnings

You cannot understand the use of lubrication without first understanding the basic concept of friction.

The Stone Age

Humans became familiar with friction back in the Stone Age, when they discovered they could create fire by rubbing wooden sticks together. As the years progressed, men used stone axes and other stone tools to produce similar effects.

It’s believed that primitive men and women hauled logs with their bark removed. Sap would have seeped from the wood and served as lubrication. They’re also believed to have used logs as rolling devices to reduce friction while transporting large loads such as stones, which was also common during the age of the pharaohs.

Other ancient lubricants were mud and crushed long leaves placed under sleds. These sleds were dragged to haul killed animals or building materials such as wood and rocks.

Our lubrication researchers have been able to trace the origin of lubricants back to 3500 B.C.E. and the ancient Egyptians and Sumerians. Using wheeled carts and chariots become common in the Middle East, and these wooden wheels would have become charred because of frictional heat.

Sumerians and Egyptians are believed to have used a variety of ancient lubricants, which included bitumen (a viscous liquid or semi-solid form of petroleum), animal and vegetable oils, and water, to reduce friction on wheels and axles. These ancient people had figured out functional solutions to their problems but still did not understand the science behind friction and lubrication.

To support rigid axles, the Sumerians used inverted forks, along with leather loops, in their carriages. These helped reduce friction along with wear and tear. The Chinese are also believed to have experimented with the lubrication properties of water around this time.

2600 B.C.E

In 2600 B.C.E., lubrication was found in a sled wheel that belonged to an Egyptian pharaoh, which an analysis proved was from beef or ram tallow (a rendered form of beef or mutton fat made up of triglycerides). This discovery led to the determination that ancient Egyptians used tallow as a lubricant for their sleds to transport materials such as wood and rocks.

2000-1700 B.C.E

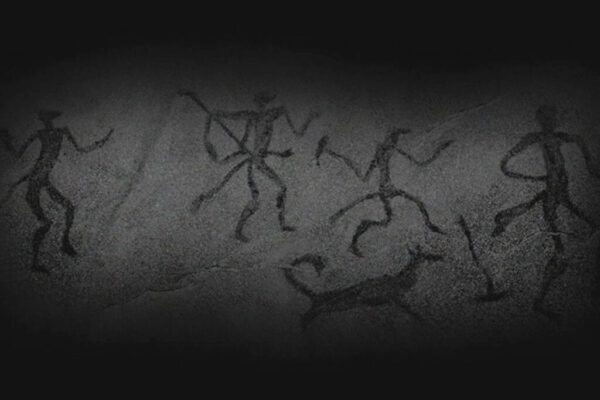

Egyptian murals from 2000-1700 B.C.E. depict statues being dragged across the ground, with a liquid being poured over a transporting device as a lubricant. It is unknown what these actual liquids were, although they are believed to have been water or olive oil.

Tribology, or the study of friction, wear, lubrication, and the design of bearings enabled ancient Egyptians to increase operating speed and reduce friction. They are also believed to have lubricated their pharaohs’ thrones with olive oil to reduce the manpower needed to push and pull them around.

1400 B.C.E

In the tombs of Yuaa and Thuiu in ancient Egypt, dated around 1400 B.C.E., examples of early chariots were discovered. They were believed to have used tallow along with lime powder and calcium soaps to lubricate chariot axles.

780 B.C.E

The Chinese developed a friction-reducing mixture of vegetable oils and lead by 780 B.C.E.

The first Olympic Games in Greece began in 776 B.C.E., occurring every four years. A common event in the Olympics was horse and chariot racing, where animal fat was used to lubricate the wheel axles.

330 B.C.E

In 330 B.C.E., Diades, a Greek engineer, developed what is believed to be one of the first roller bearing mechanisms to support warship battering rams.

The bearings of a Mesopotamian potter’s wheel from 400 B.C.E. was found to contain traces of bituminous substances (black or dark colored solids derived from petroleum or natural asphalt distillation), suggesting that lubrication from local petroleum deposits was used.

The discovery of a rotating platform in 1930 from a large ship of the Roman Emperor Caligula, dating from around 40 A.D., was found at the bottom of Lake Nemi in Italy. This was the first evidence of ancient rudimentary bearings and a thrust bearing, which is a bearing designed to support direct loads while rotating around its axle.

Into the Common Era

Animal fats and their basic variants continued to be utilized for mechanical lubrication at the start of the Common Era.

200 A.D.

In 200 A.D., the Romans continued to use chariots as a primary form of transportation, which were also lubricated by animal fats.

During the Middle Ages, from the 5th to the 10th centuries, animal fats were known to be used to lubricate the mechanisms for opening the gates of castles and on carriage wheels carrying kings and queens.

The first new changes were reported in 8th century Norway, in the year 780 A.D. At this time, Viking warriors and maritime adventurers were known to be expert boat builders. They created ships known as drakkars, a term derived from the word dragon. Raiders decorated and used these large ships.

The Norwegians are believed to have used whale oil to lubricate the sails’ hinge supports and the rudder axes. This new type of oil was obtained from the blubber of whale stomachs.

15th Century

The 15th century marked the beginning of improved commercial ship navigation. As a result, whale oil saw continued use in lubricating the pulleys and rudders of ships. It also knew shipbuilders to have used ancient oil methods that had been around for millennia known as rock oil, mineral oil and naphtha oil (flammable oils containing various distilled hydrocarbons).

As civilization continued to develop in Italy through the 15th and 16th centuries, some of the greatest revolutionary minds developed inventions and mechanical tools. One person of note from this time was the great Leonardo da Vinci, who was responsible for developing giant projects that contributed to the advance of mechanical lubrication, such as the catapult and the excavator, among many others.

Throughout his life, Leonardo studied the problem of friction. He examined the coefficient of friction (static friction) on an inclined plane, and determined the value of the friction coefficient as f = ¼. This led to the formulation of the laws of dry friction.

He continued to study friction across horizontal and inclined planes, along with wear on slide bearings. These investigations resulted in his first and second friction laws.

1490

In 1490, he changed the rolling bearing, replacing the moving connection between the two parts with a mechanism that used balls to reduce rolling friction.

His conclusion was that friction was reduced when the balls did not touch, which led to his development of separator elements to let the balls move freely.

As iron and brass replaced wood for many heavy-use machine parts, animal fat oils proved to no longer be adequate. People began to experiment with a mixture of animal and vegetable oils, and some that were developed and are still in use today, such as tallow, olive oil, castor oil (vegetable oil pressed from castor beans), peanut oil, and rapeseed oil (canola).

16th Century

Following the 16th century, whale oil (from whale blubber) use continued, and porpoise oil, retrieved from the body, head, or jaw of a porpoise, came into the picture.

French physicist and governor of Lille, Guillaume Amontons, conducted extensive research on mixed friction. Amontons found that friction force is dependent on normal force along with surface roughness, and developed his theory of “interlocking.”

This led to his derivation of the coefficient of friction to be f = 1/3. Amontons presented his findings in 1699 to the Académie Royale in Paris, but they believed he had just unearthed discoveries attributed to Leonardo da Vinci.

17th & 18th Century

In the 17th and 18th centuries, French natural philosopher John Theophilus Desaguliers developed a tribology model that detailed the effect of cohesion and adhesion on friction. He defined the concept of higher frictional force on well-polished surfaces, as two well-polished surfaces placed together might prove difficult to separate.

In 1687, Sir Isaac Newton, an English physicist and mathematician, defined the term “viscosity,” which centered on the belief that friction had both molecular and mechanical causes. Viscosity today can be defined as “the state of being thick, sticky, and semifluid in consistency, due to internal friction.”

In the 18th century, Swiss mathematician and physicist Leonhard Euler studied the impact of inclined planes on friction, which he determined to be double. He termed this the “friction coefficient.” Charles Augustin Coulomb, a French military engineer and physicist, continued to expand on Amontons’ ideas about surface roughness and mixed friction, along with the connection between horizontal force and weight percent.

In 1794, Philip Vaughan, a Welsh inventor and ironmaster, was granted the first patent for a deep-groove ball, which was an advancement of Leonardo da Vinci’s discovery. This was followed by English horse carriage axles becoming fitted with ball bearings, which required lubrication.

With the Industrial Revolution beginning in the 18th and 19th centuries, mechanization of industry and transportation became a reality. As the textile machinery industry expanded, so did the use of lubricants to ensure the smooth functioning of the machines. Mineral oils from shale and coal were extracted through distillation and refined into petroleum.

We can trace crude oil, or unrefined petroleum, being used as a lubricant back to 1845 and a cotton spinning mill in Pittsburgh, Pennsylvania. The mill owner experimented with this oil by mixing it with the sperm oil he had used to lubricate his spindles.

Sperm oil is a waxy liquid that comes from sperm whales. The mill owner discovered the new concoction to be better than just using sperm oil and continued to use it secretly for ten years.

On August 27, 1859, former American train driver and businessman Colonel William Drake struck oil, marking the birth of the American petroleum industry in Titusville, Pennsylvania. The first oil well was drilled twenty-one meters deep, and soon, 3,200 liters of oil were being extracted daily.

Petroleum-based oils were not accepted on their own as they did not perform like many of the animal-based products. That was until vacuum distillation—or reduction under pressure—showed that useful fractions could be separated without the heavier product oxidizing and deteriorating. Five years after Drake’s big discovery, hundreds of companies became dedicated to oil extraction.

19th Century

As the 19th century progressed, it became common practice to lubricate the bearings of trains every 160 kilometers.

Elijah McCoy, who you may be familiar with from the expression “the real McCoy,” was a Canadian-born African-American inventor and engineer. In 1872, McCoy invented an automatic lubricator that was used to apply oil through a drip cup to locomotive and ship steam engines. He patented this device as an “Improvement in Lubricators for Steam-Engines.”

The term “the real McCoy” is believed to have come about because railroad engineers did not want low-quality copycat versions of this device, so before purchasing it they would ask if it was “the real McCoy.” McCoy went on to own fifty-seven U.S. patents, many of which were related to steam engine lubrication.

As machinery and technology continued to develop further, so did the use of industrial lubrication.

The period between 1850 and 1925 was considered a time of “technical progress,” as the railways became the focus of society’s transportation. Bearings and slideways used liquid lubricants, advancing from solid lubrication (grease precursors). Because of supply and demand, inexpensive lubricants comprising mineral oils were mass produced.

In 1877, French chemist Charles Friedel and American James Mason Crafts developed the first synthetic hydrocarbons. This was the first attempt at a synthetic lubricant alternative.

Between 1883 and 1905, new theories on hydrodynamic lubrication came to light. This was because extensive research showed that adding a lubricated film separated the surfaces of machinery, reducing friction and preventing wear. The added pressure split the two forces apart, coining the phrase hydrodynamic lift.

One person of note from the early 20th century was Oskar Zerkowitz, who emigrated to the United States from Austria and changed his name to “Oscar Ulysses Zerk.” He soon became a famous inventor and was known for a grease fitting he called “the zerk.”

This device became the basis for those used on almost every car, truck, plane, and other mechanized vehicle today. When he passed away in 1986, it was estimated that twenty billion “zerks” had been manufactured, and are still in use today.

Modern Day

Now let’s dive into the current state of mechanical lubrication applications.

Powerful cannons and machines came into heavy use in the 20th century, during the World Wars. Lubricants became even more essential to ensure that these devices continued to work in battle. As new technologies emerged, so did more new industrial lubricant concoctions that aimed to minimize friction and increase the life of equipment.

Early 1900s

In 1903, when flying their first aircraft, the Wright brothers used lubrication techniques to get more power than expected and take flight, four miles south of Kitty Hawk, North Carolina.

During the 1920s, manufacturers of lubricants processed base oils through vacuum distillation to improve performance. Some of these materials could be combined with soap and turned into grease.

As demand grew, in particular from the bustling automotive industry, manufacturers of lubricants also started to process their petroleum-based oilsMC25® to improve performance. Over the next decade, numerous processes, some better than others, were developed. Solvent refining, or the removal of undesirable contents, proved to be one of the most effective methods.

In 1923, the Society of Automotive Engineers defined engine oils by thickness, from light to medium to heavy. These types of oils needed to be replaced every 800 to 1,000 miles and contained no extra additives.

In 1929, Standard Oil of Indiana became the first to develop synthetic hydrocarbons. By 1930 solvent processing had emerged as a safe and successful method to improve base oil performance. Many modern oil producers today still use this recyclable process.

1930s

In the 1930s, more additives emerged, such as oxidation inhibitors, corrosion-resistant additives, point enhancers, and improved viscosity indexes, to name a few. Germany soon emerged as a market leader. They were known to have developed synthetic fuels, rubbers, lubricants and waxes during the 1930s and early 1940s.

In 1938, American chemist Dr. Roy J. Plunkett pioneered the discovery of polytetrafluoroethylene (PTFE), or Teflon, while experimenting with tetrafluoroethylene as a refrigerant.

As advanced lubricants become more common, many experimented on their own to self-lubricate machinery. As we progressed through the 1940s, new lubricant formulas to extend the life and performance of car engine oils were developed.

Without extra additives, these engine oils did not last as long. In the late 1940s, the railway industry used systematic oil analysis to prevent future engine failures.

Following the conclusion of World War II, scientists examined the solid lubricant molybdenum disulfide (MoS2), which is a trace mineral found in common foods such as milk and nuts. This was an effective lubricant for high-pressure conditions, making it the perfect product for space research.

In 1947, the American Petroleum Institute (API) categorized engine oils into the following use sections: regular, premium and heavy-duty. Manufacturers used various additives to improve performance and lifespan to meet the needs of these categorical specifications.

1950s & 1960s

By 1950, multi-grade automotive engine oils came into the picture and lubrication technology advanced. These were added to polymers, or large molecules, to raise the oil viscosity index to improve performance at both hot and cold temperatures.

Naturally occurring petroleum oils were pushed to the side because of new solvent refining technological advancements. They were used on new modern devices ranging from ships to missiles and other forms of weaponry. The aerospace and aviation industries used synthetic lubricants as well.

The Jost Report in 1966, led by Dr. Peter Jost, included the first mention of the term “tribology.” This was a study the British government commissioned to investigate wear damage and referred to friction, wear and lubrication.

Hydrocracking, or the process of combining catalytic cracking and hydrogenation, became common in the 1970s and 1980s. This was a method of manufacturing Group II base oils with strong stability, purification and low-temperature performance, compared to Group I base oils.

1990s

In the 1990s, the use of modern hydroisomerization technologies began. The purpose of this method was to dewax base oils by transforming wax molecules into good quality base oil. The API officially classified Group II, Group III, Group IV and Group V base oils.

As we entered the 21st century, the evolution of mechanical lubrication progressed further. The industry continues to advance to meet the needs of modern machinery. Oil and grease products are more productive, reliable, energy efficient, and environmentally conscious than ever.

Grease and other modern semi-solid lubricants are derived from thickening agents in mineral oil or a synthetic liquid base, such as fluorocarbon liquid or silicone liquid. Grease has become popular because of the negative impact of oil leaks.

Some thickening agents still include vegetable and animal fats, along with resins, gels, waxes, fatty acids, saponified fats (triglycerides mixed with fatty acids), and naphthenic acids. Some other common ingredients included are metallic soaps made with calcium, barium, sodium, or lithium.

To maintain reliability, synthetic lubricants are produced from crude oil by way of chemical synthesis. These oils have a low friction coefficient, low vaporisation tendencies, low flammability, water miscibility, strong metallic wettability and high thermal stability.

Many modern machines such as boats and planes are now even simply lubricated by air, which helps with energy saving and pollution reduction. With ships, in particular, air bubbles are created below the surface of the water in order to help the ship sail. These air lubrication systems are expected to reduce CO2 emissions by ten to fifteen percent, along with fuel savings.

Further Modern Applications

Now that we’ve outlined the history of industrial and mechanical lubrication and you’re an expert, we want to bring your attention to some common modern-day lubricant applications.

Military & Defense

Modern advanced weaponry and machinery require lubrication to maintain proper functionality and effectiveness. Lubricants are beneficial in heavy load, extreme pressure, anti-corrosion and extreme temperature performance situations such as desert war zones and naval warfare saltwater environments, and in advanced fighter jet gun systems.

Since they will be in high-pressure, life-or-death situations, it’s important that those serving in the military and special defense forces know how to lubricate their weapons, which includes applying lubricants to the correct moving parts. Lubricants can also be used on high-powered machinery such as tanks, fighter jets, helicopters and machine guns.

There are also different lubricant options for light- and heavy-weapon use, and you can’t lubricate dirty equipment, which is why cleaners like MC25® are essential. In order for mechanical lubrication to penetrate metal surfaces and have the desired effect, your devices must be free of dirt and debris.

Industrial

Anti-friction metal treatment (AFMT) lubricants and greases improve and extend the life of your equipment and protect your investments.

Heat caused by friction reduces the reliability of your equipment and is one of the top causes of machine failure. Metal treatment lubricants and greases penetrate metal surfaces, leaving behind a semi-dry coating reducing friction that lasts six to ten times longer than traditional oil or hydrocarbon based lubricants.

The proper lubrication of industrial equipment can also help reduce maintenance downtime and help you save on electricity, fuel and energy costs. Some common industrial machine parts that can be lubricated include gears, hinges, pulleys, bearings, shafts, axles, chains, cables, joints and pistons.

Tactical & Law Enforcement

Similar to the military, tactical teams and law enforcement professionals at the federal, state, county and local levels all need keep their weapons lubricated to ensure proper functionality.

With lives at stake on a daily basis, weapon performance is paramount.

Gun and Sport

Gun enthusiasts should treat their weapons as long-term investments, which means they need to lubricate all equipment. As anti-friction metal treatments and smooth action solutions, lubricants can be applied to any device that has a sliding mechanism and gets constant wear.

Products like TW25B ® light synthetic lubricant and grease have been engineered for extreme military uses and conditions. It’s the most durable performance lubricant available, and ensures firing reliability in severe temperature conditions (-90°F (-67°C) to +450°F (232°C)), proven from live-fire trials. TW25B® enables the firing of six to ten times more rounds between cleanings, while using a fraction of our lubricant, when compared to other products.

General Applications

Lubricants are not just for advanced military weaponry and high-powered jets. There are many other commercial applications for the average consumer. Some common uses of lubricants can be found in or on locks, hinges, chains, cables, gears, and the axles of any mechanical device.

Wherever there is friction, dirt or debris, lubricants are needed.

Conclusion

With a great deal of trial and error, mechanical lubrication has developed over thousands, if not millions of years, from ancient humans dragging logs, to cotton mills in early America, to what it is today across numerous industries and sectors.

Modern lubricants have unlimited applications and uses, whether on machinery, weapons, transport vehicles, appliances, or any other form of industrial technology.

They’re no longer just naturally occurring animal fats, but scientifically formulated synthetic greases and oils that keep our society and advanced moving parts functioning at the highest capacity possible.

Lubrication techniques allow machines to be more efficient, last longer, be more reliable and allow you to spend less money on continued maintenance costs.

Don’t forget: If it moves, it needs to be lubricated.

Notice anything we missed, or have something you’d like to add? Let us know in the comments section below!

Comments are closed.