Are your machines breaking down sooner than they should? Are the moving parts wearing themselves down faster than you can replace them?

It’s a good possibility you have a problem with your machines lubrication. Without proper oil or grease, your machines will continue breaking down until you find a good lubricant to help it do the job.

If you doubt the benefits of a high-quality lubricant, keep reading. We’ll go through all the reasons this slippery stuff is important to your hard working machines.

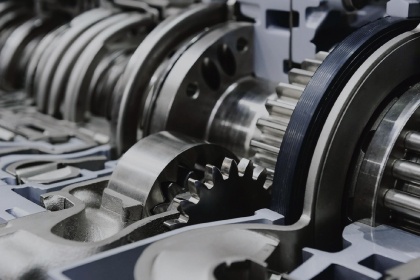

Minimizes Friction

The main point of lubrication is to stop friction damage between moving parts. People use lubricants in a variety of different applications, from bike chains to sewing machines.

Lubricants are even more important when your entire company relies on the condition of your machines. You want to reduce as much friction as possible so there’s no excessive damage done to your machine.

When using a low-quality lubricant, there isn’t enough of a barrier between the moving parts.

Always choose a higher-quality product to get the best results. Renewing your lubricants regularly is also important so your machines are always working at peak performance.

The best part is that minimizing friction created by your machine leads to additional benefits.

Slows Down Wear and Tear

With friction under control, the general wear and tear of your machines improve. You’ll have far fewer problems with worn-out parts with a proper lubricant than without.

The slippery substance acts as a barrier between the different moving parts, aiding in their movement. This stops the terrible grinding of metal-on-metal that wears down those moving parts in no time at all.

It also acts as a barrier to rust and other kinds of corrosion, keeping your machine protected as long as the lubricant is in place.

Prevents Machine Downtime

Downtime is the bane of any production line.

When the machines are down, nothing else can happen until they’re up and running again. Depending on the severity of the damage, downtime can take anywhere from a few minutes or several hours.

It’s terrible for any company, as more downtime means less money for everyone involved.

As the lubricant works to keep the machine from wearing itself down, you’ll no longer have frequent periods of downtime. The likelihood of it happening goes down as your machine keeps chugging along with no problems at all.

No broken parts, no need to shut everything down to fix the problems.

By greasing up your machine, you’re prolonging its life. Instead of the entire company grinding down into a standstill, production continues without fail.

Generates More Product

Without extended downtime, you ensure your machines are always putting out an optimal amount of product. More product means more money, and who doesn’t love that?

There’s nothing worse than missing a quota or a deadline because of a faulty machine – even more so when the problem is easy to prevent with a lubrication product.

If you’re unable to keep up with your production quota, it might cause you to lose clients or other opportunities. Don’t let that happen because of something easy to fix!

Saves Money

Not only are you making more money with the help of a good lubricant, but you’re also saving money. This is good news for any company, no matter what they sell.

There’s no need to buy replacements for broken parts if your machines don’t break down. It’s not foolproof, however. There’s bound to be hiccups in production as big machines with moving parts need repairs from time to time.

But by giving that machine the shield of a good lubricant, you’re minimizing a lot of the most common types of repairs. You’re also minimizing the number of replacement parts you must invest in.

It’s a win-win situation for you and your company.

Controls Machine Temperatures

Less friction created by running your machines means that there’s also less heat produced.

When there’s a great amount of friction caused by metal grating against metal, those temperatures skyrocket. This can lead to overheating and has the potential to significantly damage the machine.

Controlling the temperature of your machines also keeps your employees safe. It ensures they don’t get too hot while working the machines from exposure to high temperatures.

Blocks Contamination

Lubricants also keep contaminants from getting into the products you’re creating.

There’s no chance of tiny bits of metal getting into your products because those metal parts aren’t wearing down. This is important if you create something for the food industry, but it’s also important for the production of all types of goods.

Lubricants also can capture other kinds of contaminations, like dust and grime. Instead of making its way into your product, the contamination stays in the lubricant’s fluid.

The motion of the machine’s inner workings often leads dust towards a proper filter, leaving your products clean and pristine.

Lubrication is an Important Part of Any Machine

Without proper lubrication, your machines end up costing you a lot more than you realize.

As you can see by the list above, there are many benefits to keeping your machines running strong. Good grease is one of the most important parts of strong production.

If you find your machines accumulate a lot of downtimes, make the switch to a high-quality lubricant. It makes all the difference, and your machines will thank you for it!

Contact us today to find out about our own high-end lubricant products that’ll have your machines singing in no time!