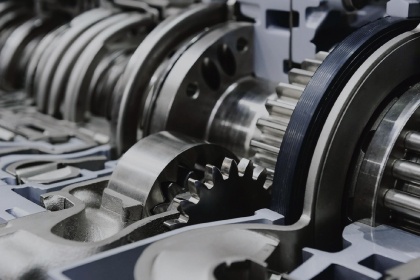

When you invest in new machine lubricants, you do your best to keep your machines as clean as possible.

Industrial manufacturers know that it doesn’t take long for equipment to become grimy, dirty and full of debris.

If left untreated, the result is lubrication contamination, which is costly and time-consuming to repair.

Here are some ways to minimize risk and keep your machines operating as they did the day you bought them.

What Causes Contamination in Machine Lubricants?

Solid particles enter industrial lubricants in a variety of ways.

Built-in contamination could already be present, or can occur from introducing a new oil.

Machine-borne particles can enter the lubrication system, along with ambient air created by the machine.

If you notice dirt in your lubricant, it likely stems from the equipment itself, which is why it’s important to keep all work surfaces as clean as possible.

Besides particles, water contamination is another culprit. This often originates from oil stored outside and comes into contact with adverse weather.

Water spillage can occur during the production process. High-pressure machine cleaning (common in the food and beverage industry) can also lead to water contamination.

Steps Toward Contamination Control

Taking proper measures to control your risk of contamination is important. A clean lubrication system can extend the life of your equipment and improve operations.

How?

Machines require a lubricating film between any two precision-bearing surfaces, which keeps them separated and protected from one another. To be effective, the film cannot contain any particles or water.

If it does, the bearings are more susceptible to breakdowns and overall performance suffers. Here are a few ways you can manage this process within your operations.

General Maintenance

Start by establishing an equipment maintenance plan that prioritizes routine surface cleaning. Wipe down all machines so that dirt won’t accumulate.

Use an enzymatic cleaner and degreaser to clean and detoxify your equipment and work site.

This responsibility falls on the operator and maintainer, and it applies not only to the machinery, but also the lubricant storage area and transfer equipment.

Operator Training

Contamination isn’t always a result of blatant negligence. Operators and maintainers aren’t always aware of the preventative steps they can take to keep systems clean and clear.

Everyone who works with your mechanical systems needs to understand the risks and consequences associated with contamination, along with specific ways to mitigate and correct it.

Proper Lubrication Storage

Make sure your machine lubricants aren’t exposed to contamination before they even enter your mechanism.

Don’t rely on generic, loose containers. Keep them in dedicated and color-coded storage and transfer equipment to make sure you’re grabbing the right bottle. Tightly close each container to prevent spills.

This keeps your lubricants protected from the elements and prevents cross-contamination.

Wipe Down Accessories

Before use, make sure all grease guns and nipples are clean and free of debris.

Wipe each part down with a lint-free rag to make sure you aren’t introducing any particles into the machine lubricant.

Strategize Oil Changes

The more often you change your oil and filter, the cleaner they will be, right?

While this is an important step, doing it too often makes your system vulnerable, but waiting too long allows contaminants to build up. Your filtration system will wear out and your lubricating fluids will degrade.

How do you find a functional medium?

Perform oil and filter changes on an as-needed basis. Require that operators and maintainers perform regular condition checks to better understand each machine and their routine requirements.

Lubricant Testing

Before introducing metal lubricants or bulk fluids into your machine, it’s important to first test each one for cleanliness.

Make sure they arrive from your industrial lubricants supplier in a clean state prior to use on your machinery, and verify additive-package formulations.

Check that they pass your in-house tests and meet all required industry codes and specifications. By doing so, you set your systems up for success as early as possible.

Equipment or Workspace Alterations

The behavioral modifications we’ve highlighted should be enough to lower your risk of machine lubricant contamination.

If time passes and you still noticing excess debris or water contaminants, consider making alterations to your equipment or workplace setup. One option is to install a room ventilation system.

These systems operate on positive or negative room pressurization to help reduce or eliminate airborne contaminants. An exhaust air ventilation system can perform the same function.

You may alter your machine design to make operations cleaner.

Does your production process use water or sand?

If so, you can find water deflector shields that help direct contaminants away from bearing equipment and lubricant reservoirs.

You may also replace your fill-cap and drain-port plugs with positive-lock fill caps and drain connections that attach to a closed-system transfer cart.

This applies to conventional breathing systems you can replace with a closed-loop expansion tank, ideal for larger reservoir systems.

A Lubrication System Designed to Deliver

Your machine lubricants are the linchpin that keeps your equipment functioning in top condition.

When they’re weakened by contaminants, it doesn’t take long for your entire operation to suffer the consequences.

The good news? By taking small steps today, you can help reduce your risk and keep your systems clean and functioning for years to come.