How Good is Your Gun Lube?

It’s been said that the making and selling of gun care lubricants and cleaners is a snake oil business — like the old-time medicine shows, everybody’s got a story to tell…everybody makes claims about being the best, the most effective, the stuff you just have to buy and use.

Well here’s a little-known fact. It is relatively easy to make a gun lubricant that does one thing well…or one thing reasonably well. Example: certain “CLP” formulations (for “CLEAN, LUBRICATE AND PROTECT”) actually clean a lot better than they lubricate — but, okay, at least something’s getting done. Motor oil and mayonnaise will also make things slippery for awhile.

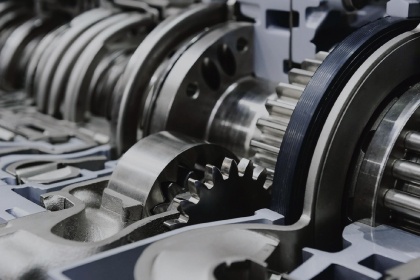

The true test of a superior performing firearm lubricant is finding one that does numerous things well, all at the same time. From a chemical engineering standpoint, that’s hard to accomplish, because all base materials and performance additives used to formulate a gun lubricant interact in often unpredictable ways at the molecular level.

Let’s break this down.

BRAND X GUN LUBE wants to provide extreme temperature performance — reliable firing at temperatures ranging up to +450-Degrees F and down to to – 60 F. Okay. You begin building that in your lab and, hooray, you hit that particular performance spec. But BRAND X also wants to provide strong anti-corrosion protection to gun parts. That’s a different trick than engineering cold temperature performance — and what happens much of the time, in the science of lubricants, one thing cancels out another thing at the molecular level. Just when BRAND X is ready to begin bragging about the cold temperature performance of its gun lubricant, the same product’s anti-corrosion performance falls apart because of offsetting chemical reactions at work. Fix one problem, create another one.

Products like MIL-COMM’s TW25B Synthetic Gun Grease really rise above the rest because of the scientifically balanced, compatibly engineered chemistry of their base materials and various performance additives. Remember what we said up top — easy to make a one-dimensional gun grease or gun oil. The real trick is to engineer one that does 8 or 10 things well at the same time.

In MIL-COMM’s case, the R&D work the Company has done with U.S. military program managers and defense contractors set the bar high — warfighters and armaments manufacturers have little use for one-dimensional or two-dimensional lubricant formulations. Too easy to get people killed that way. Instead, the requirement was for a performance matrix in which a lot of positive lubrication things were happening in the extreme trauma of guns being fired.

So when you go shopping for a superior-performing gun lubricant, check to see if its performance features add up to the likes of TW25B synthetic gun grease and MC2500 synthetic gun oil. Here’s the checklist for your shopping:

- Optimzes firearm performance with very long-lasting lubrication and corrosion protection;

- Performs depenably in all climates, under all weather conditions, on all types of firearms;

- Works reliably in temperatures ranging from -85 F -(54 C) to +450 F (+232 C)

- Greatly reduces frition and wear…extends the life of parts;

- Won’t gum up;

- Repels sand, dust, grit, debris…minimizes accumullation of gun powder residue;

- Resists wash-off, wear-off, burn-off and evaporation between cleanings;

- Reduces time and frequency of maintenance with easy wipe-off cleaning;

- Permits storage of firemarms in fire-ready condition for extended periods;

- Minimizes carbon residue, galvanic corrosion and build-up of copper and lead;

- Generally harless to wood, rubber, plastic or composite parts;

- All-synthetic, non-hazardous, non-flammable and environmentally safe.

If you are serious about maintaining firearms for optimal performance, this stuff matters! It really IS worth finding out: how good is my gun lube?